If your watch is a luxury brand, you need a wooden watch box to enhance your brand image and increase sales. Wooden watch boxes can convey a higher sense of quality. Wooden watch boxes are very environmentally friendly. Watch packaging boxes made of this wood can be shaped into various shapes. Its life is also very long. It is waterproof and anti-corrosive, and it protects the watch inside from being oxidized by moisture in the air. The wood has stable performance and the color of the appearance does not fade easily.

When looking for a wooden watch box manufacturer, the first criterion is whether they can provide all three aspects of your packaging or product label design problem: creative, practical and cost-effective solutions. Please consider the following factors when choosing a wooden watch box manufacturer:

Generally, a good factory such as Precious will have professional designers. Before officially manufacturing the wooden watch box, they will first draw a detailed woodworking drawing for the customer to confirm and make modification suggestions. After confirmation, production will begin. The drawing can more intuitively express the structure of the wooden watch box and avoid misunderstandings caused by text description communication. This can save time and improve efficiency. For example, some watch wooden boxes may need to be designed into special shapes such as round, square, polygonal, or need to be engraved with exquisite patterns, printed LOGO, etc. Detailed drawings can provide accurate design references for carpenters to ensure that they can make watch wooden cases that meet the requirements.

The drawings can clearly show the structure of the watch wooden cases, including the connection method and position of the lid, bottom, side panels, partitions and other parts. This helps carpenters to reasonably arrange the splicing and fixing of wood during the production process, ensuring that the structure of the watch wooden box is firm and stable. For example, some watch wooden boxes may require special structures to fix watches, such as grooves, pads, etc. Detailed drawings can accurately indicate the location and size of these structures, so that carpenters can accurately make watch wooden boxes that meet the requirements.

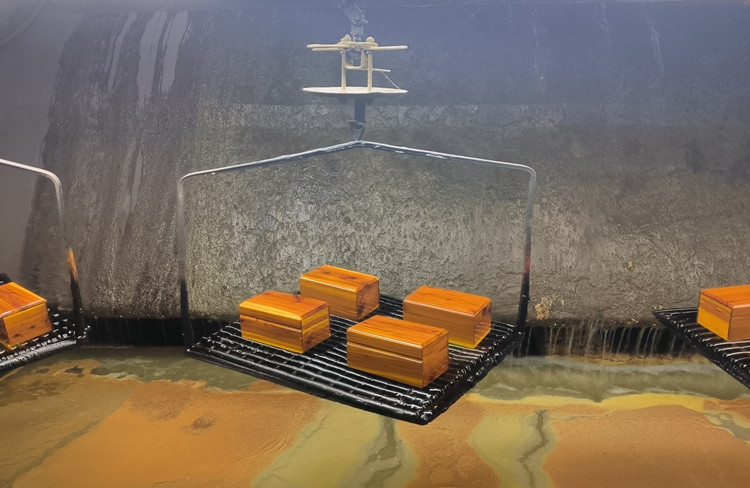

In addition to providing detailed woodworking dimension drawings, advanced machines and equipment are also an important guarantee for providing you with high-quality and reasonably priced watch wooden boxes. Precious has 3 CNC sawing machines, 3 laser engraving machines, 5 sanding machines, 5 polishing machines, 3 hanging conveyor chains and 2 water curtain spray booths.

The CNC sawing machine can accurately cut wood into the required shape and size according to the preset program and size, with high precision and high efficiency. For example, for the side panels, bottom panels and other parts of the wooden box, the CNC sawing machine can ensure the accuracy of the cutting size and improve the assembly accuracy of the wooden watch box. The laser engraving machine uses laser technology for processing. It can perform shallow carving on the surface of wood, carve delicate patterns and textures, and will not cause significant damage to the wood. It is suitable for fine decorative carving of wooden watch boxes. The sanding machine is used to polish and sand the surface of the watch wooden box, remove burrs and defects on the surface of the wood, and make the surface of the wooden watch box smooth and flat. There are many types of sanding machines, such as flat sanding machines, special-shaped sanding machines, etc., which can meet the polishing needs of wooden watch boxes of different shapes and sizes. After the surface of the wooden watch box is polished, the use of a polishing machine can further improve the gloss and smoothness of the surface of the wooden box, making the watch wooden box look more beautiful and delicate. The water curtain spray booth can effectively collect the paint mist generated during the painting process and reduce environmental pollution. There is a water curtain device inside the water curtain spray booth. The paint mist will be adsorbed by water after contacting the water curtain, thereby achieving the purpose of purifying the air. At the same time, the water curtain spray booth can also provide a good working environment for the painting operation and improve the quality of the painting.

Factories with design capabilities can design unique products according to your specific requirements, such as size, shape, color, function, etc. Wooden box factories can design customized watch wooden boxes for customers. According to the brand, style and size of the watch, combined with the watch brand story, highlighting the watch brand image, they can design a wooden box that perfectly matches it to meet the personalized needs of customers.

There are reasons why you should compare aspirant wooden watch box suppliers. The first reason is that comparing suppliers can get you a better deal. Your suppliers will be able to compete for business by decrease their prices. This gives you a way to save on packaging costs, which can help cut down costs elsewhere in your company.

The second reason is that comparing suppliers allows you to find the one that best suits your needs. When you compare suppliers, you can look at their products in terms of price and quality, as well as other factors such as shift time and reputation for customer service. This means you can find suppliers who can provide you with what your company needs at an cost-effective price!

Whenever you are looking for a wooden watch box supplier, it is crucial to choose the right one. You need someone who can assist you with your packaging requirements while providing you with high-quality materials. However, there are many companies that maintain to offer this service but actually do not. This can be a problem if you don't know which companies are legal and which are illegal.

When looking for a wooden watch box wholesale supplier, there are a few things to consider before making any decisions. One of the most common mistakes people make when choosing a package provider is relying solely on word-of-mouth proposals from friends or family members who have used them before, without actually knowing anything about the factory other than what their friends have said about them.

Generally speaking, watch wooden box factories should have ISO9001 quality management system certification and FSC certification.

Possessing certificates such as ISO 9001 quality management system certification indicates that the factory has a complete quality management system and can stably produce products that meet quality standards. This can not only increase customers' trust in product quality, but also help the continuous improvement of internal quality management in the factory, reduce defective rates, and reduce production costs. For example, when cooperating with some watch brands with high quality requirements, quality certification is an important prerequisite for cooperation.

In the current context of environmental protection and sustainable development, FSC certification is increasingly valued. This certification ensures that the source of wood is legal and sustainable, that is, the wood is harvested from well-managed forests. For wooden watch box factories, obtaining FSC certification can meet customer demand for environmentally friendly products and enhance the company's image of social responsibility.

When choosing a wooden watch box factory, it is of vital importance to consider the cost. Cost is one of the key factors that determine the price of the product. The cost of wooden watch boxes includes raw materials, processing, transportation and other aspects. If the cost is high, then the pricing of the watch box will inevitably increase accordingly, which will directly affect the overall selling price of the watch. For watch manufacturers, reasonable product pricing is an important means to attract consumers.

Reducing costs can directly increase profit margins. When choosing a wooden watch box factory with a lower cost, while keeping the sales price of the watch unchanged, the reduced cost of the watch box will directly convert into profit for each watch sold. For companies that produce watches on a large scale, this increase in profit is considerable.

When watch companies can obtain high-quality wooden watch boxes at a lower cost, they can invest more resources in other aspects of the product, such as improving the quality of the watch, increasing the function of the watch, or providing better after-sales service, thereby improving the overall cost performance of the product and enhancing its competitiveness in the market.

When choosing a wooden watch box factory, it is really important to control the quality of materials, which is reflected in many aspects

Avoid physical damage: high-quality wood materials have appropriate hardness and strength. If the wood is too soft, the watch box may be deformed when subjected to slight external force, and it cannot effectively protect the watch from physical damage such as squeezing and collision. For example, during transportation or daily placement, a hard object may press the watch box. If the wood quality is poor, the watch dial, watch mirror or watch strap and other parts may be damaged.

Moisture-proof and insect-proof: The quality of wood is directly related to the moisture-proof and insect-proof ability of the watch box. Poor-quality wood may have too high a moisture content and is prone to moisture and mold, which will not only affect the appearance and service life of the watch box itself, but may also cause the watch to rust or damage the internal precision parts.

Texture and color: High-quality wood has beautiful natural texture and color. For wooden watch boxes, the texture of the wood is an important part of its appearance. Different textures such as straight grain and mountain grain can give the watch box a unique visual effect.

Durability: Wooden watch boxes with good material quality are more durable. The wood that has been strictly selected and processed has a tight fiber structure and is not easy to crack or deform. During long-term use, watch boxes are often opened and closed, and experience different temperature and humidity environments. If the quality of the wood is not up to standard, it is easy to be damaged, such as cracking of the corners, deformation of the box cover and inability to close tightly, etc.

When choosing a watch box factory, it is very important to explain the surface treatment process and printing process in detail, which will help ensure the quality, appearance and functionality of the watch box. Here are some aspects of the surface treatment process that need to be explained in detail

Number of paint layers

The number of paint layers determines the color saturation, glossiness and protection effect of the watch box surface. Generally speaking, the more layers, the richer the color and the better the protection effect.

For watch boxes that require high gloss and rich colors, 3-5 layers of paint may be required; while for boxes that pursue natural texture, 1-2 thin layers may be enough. At the same time, pay attention to the drying time and construction conditions of each layer of paint to ensure the consistency of the spray painting effect.

Bronzing process

If the watch box needs bronzing, the pattern, text content, location and quality of the bronzing should be explained in detail. Bronzing can increase the luxury of the watch box and is often used for brand logos and decoration of specific patterns.

The quality of gold foil includes factors such as gold content and thickness. High-quality gold foil can provide brighter and more lasting bronzing effect. At the same time, ensure that the factory has sufficient technical capabilities to accurately control the position and shape of the hot stamping to avoid deviations.

Anti-fingerprint treatment

In high-end watch wooden boxes, anti-fingerprint treatment is an important aspect to enhance user experience. You can ask the factory to use special coating or treatment technology to make it difficult to leave fingerprints on the surface of the watch wooden box.

This treatment can keep the surface of the watch wooden box clean and beautiful, and avoid fingerprint stains affecting the overall appearance of the wooden box.

Packaging and Shipping Requirements

If the box has specific packaging or shipping requirements, be sure to inform the watch wooden box manufacturer of these requirements. Some of our customers need to add a pallet to make shipping safer, while others do not need it to save costs. If you need a pallet, please tell us what kind of pallet do you need, paper pallet, plastic pallet or wooden pallet? Different materials have different prices.

There are many factors to consider when choosing a packaging factory. Whether your business is large or small, or somewhere in between, we believe these are the most critical aspects to consider when choosing a custom packaging company. When choosing a watch box factory, be sure to always follow these guidelines. This will help choose the ideal company that can meet your custom watch wooden box packaging needs. With the help of Precious Packaging's experienced design and production team, you can be sure to purchase a perfect watch wooden box.

1,Q: What is your MOQ?

A: Our MOQ is 200pcs while many other factory’s MOQ is 500pcs.

2, Q: What is the sample process for customized products?

A: First, we will communicate with the customer in detail about the requirements and determine the design plan, then purchase raw materials and make samples. After the sample is made, we will take photos and send to customer to confirm. After the customer confirms, we will send it to the customer and make modifications based on the customer's feedback until the customer is satisfied.

3,Q: What is the maximum production capacity?

A: We can produce around 80 thousand wooden watch box per month.

4, Q: How does the factory ensure the delivery time?

A: Production management will schedule all customer orders. Sales will regularly follow up on raw material procurement and production progress, take photos and send them to customers, communicate with customers in a timely manner, let customers know the production progress, and reassure customers.

5, Q: I have never bought wooden watch boxes from China before and I don’t have an import certificate. Can you sell them to me?

A: Yes, we can sell the wooden watch boxes to you, our forwarder can handle the importing for you.

6, If the wooden watch box has quality problems, how will the factory deal with it?

Our company has a complete after-sales service process. For quality issues, we will first confirm the problem. If it is a minor problem, we will provide solutions such as repair or replacement of parts; if it is a serious quality problem, we will re-produce for the customer.

We chat