Are you considering whether to use foldable rigid box to package your products? If so, congratulations, you've come to the right place! This post will give you all the relevant information about foldable rigid box in detail.

The foldable rigid box greatly reduces the logistics and storage costs due to the saving of transportation and storage space, and has the advantages of low processing cost, easy to sell, display, easy to use, reusable, etc., and has both functionality and environmental protection.

This article will discuss the relevant knowledge of foldable rigid box in depth, in this article you will learn about the definition of foldable rigid box, materials and styles, production processes and price ranges, etc. We hope that by the time you finish reading this article, you already have enough knowledge to decide whether this foldable rigid box is suitable for your product.

What is a Foldable Rigid Box ?

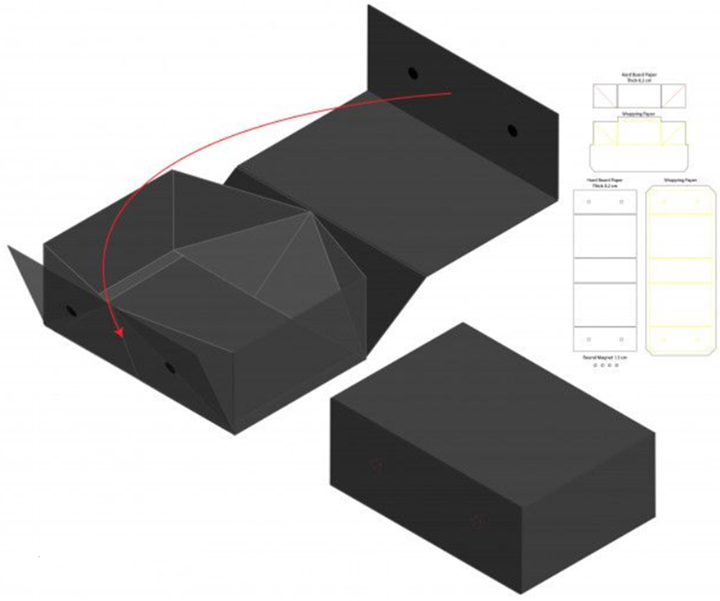

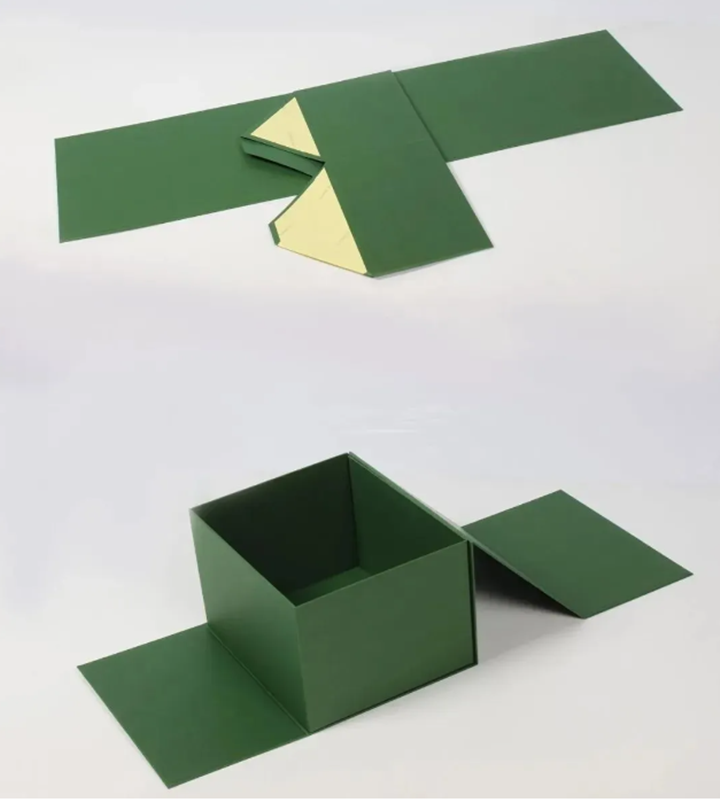

Foldable rigid box is a kind of box that can be assembled after all the lines are folded, after the box is formed, it is pressed into the box for 2 days with a shaped pendulum plate and then folded into the box, the box forms a memory, it can be easily formed, it can ensure that the ridge line of the box is clear and the angle is regular and easy to fold.

It is made of a sturdy hard material, such as cardboard or gray board, and can be folded flat when not in use. This kind of box saves space and transportation cost when transporting, and has a certain convenience and safety.

The foldable rigid box has good strength, can resist extrusion, collision and friction, provides effective protection for products, and is suitable for electronic products, cosmetics and other product packaging. Excellent performance in customization, size, shape can be designed on demand, appearance can be printed, hot stamping and other decorations. And cardboard is recyclable, cost-effective, and an environmentally friendly and practical packaging option.

Collapsible rigid box generally uses thicker white cardboard or gray board, it is recommended to have more than 800 grams, if you need to print exquisite patterns, you generally need to paste a piece of 157 grams of art paper outside the white cardboard or gray board, and then lamination or varnishing. Double-sided white cardboard and grey board are mainly composed of plant fibers. Most of these plant fibers are derived from wood and are extracted through the pulping process. It is a recycled and environmentally friendly material. If your country requires 100% recyclable rigid boxes, we recommend that you replace coated paper with white kraft paper, which can be printed directly without the lamination or varnishing.

You may are also very interested in the types of collapsible rigid box, so here are eight common types of folding boxes.

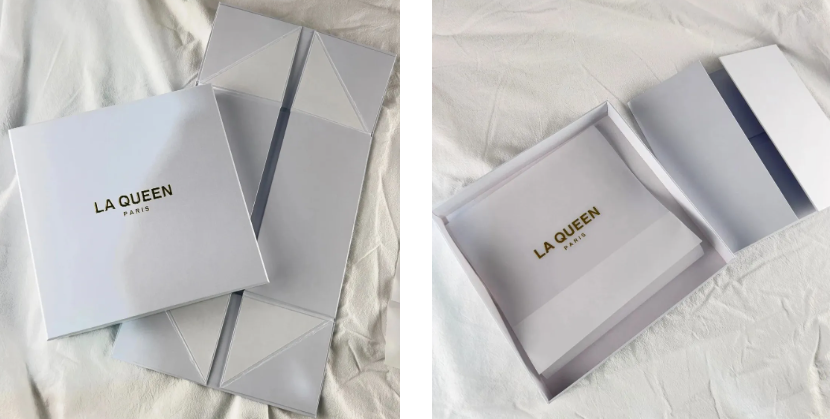

The five-plate collapsible rigid box is also known as the classic collapsible rigid box, also known as the one-piece collapsible rigid box, and the finished product is similar to a book-shaped box after being pasted and molded. Mainly include 1PCS leather shell and 2PCS flank ; The other components are composed of magnet + iron sheet + lining + double-sided adhesive tape, etc.

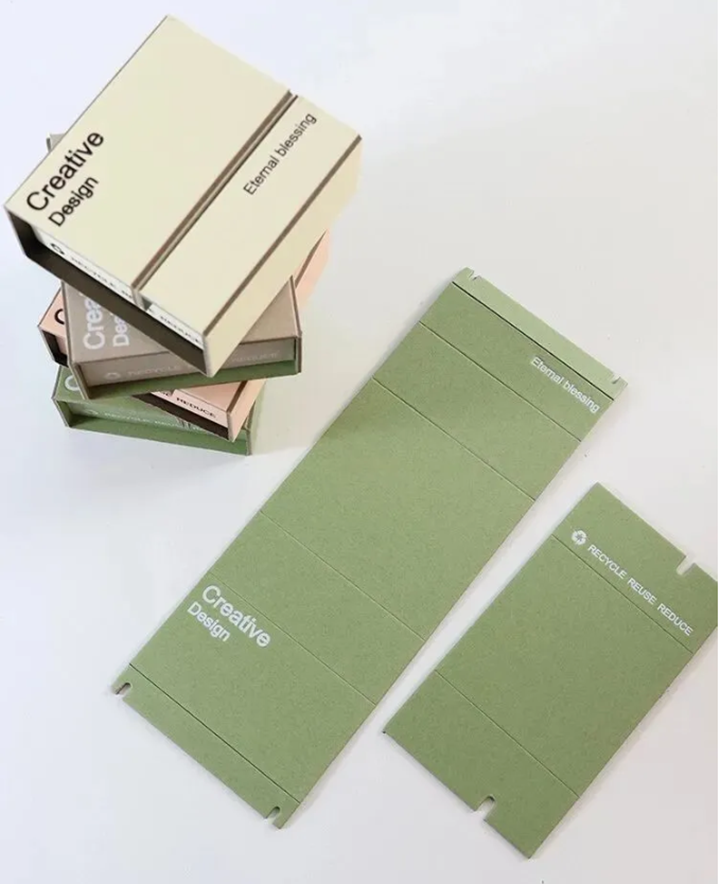

The two-piece collapsible rigid box, also known as the card-type collapsible rigid box, only needs two sheets of cardboard to make a delicate packaging box. The ingenious structural design makes the assembly very easy, and the whole process does not require any glue and magnets, which is practical and environmentally friendly. The cardboard is slotted with special paper mounted on the front and back of the gray board, which is simple and cost-effective.

This style of collapsible rigid box is very popular in recent years, more than the usual 5-plate folding box with two more baffles and cardboard tabs, the two baffle components can be parallel or cross to the large leather shell, and the two baffles play the role of fixing the inner box after molding. The advantage is that there is no need to paste double-sided tape and magnets, and the disadvantage is that there are many processes and the price is high.

This structural design is a side-to-side folding box, and the bottom of the inner box is reserved with double-sided tape, and the inner box is pushed and glued to complete, which is convenient to use.

According to the different customers or process requirements, the cover part of the shell plate is usually disconnected, and the rest of the slots are slotted process; and all gray plates are disconnected structural design.

In addition to deforming on cardboard, folding boxes are often combined with other classic box types to derive folding packaging boxes that are more suitable for gifting scenarios.

This finished product is shaped like a lid and base box, which is mainly composed 1PCS of a lid box + 1PCS leather shell + 2PCS flank; Due to the low height of the lid, there is no need to fold, and the height of the base box is relatively high to make a folding packaging boxes structure, which is convenient for storage and transportation and saves costs.

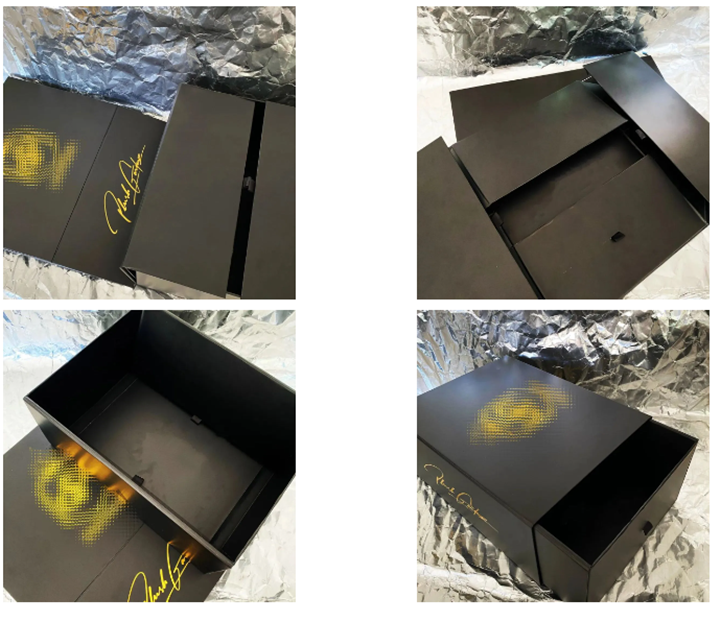

The finished folding box, which looks like a drawer box, is mainly composed of an inner box + an envelope. The envelope is also made of gray board and covered with paper, and can also be folded. The inner box adopts a five-plate folding box structure, and two inner baffles fix the box body, without the need for double-sided tape.

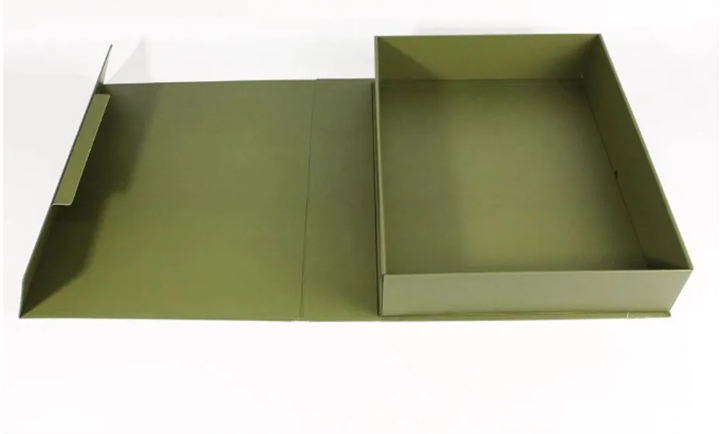

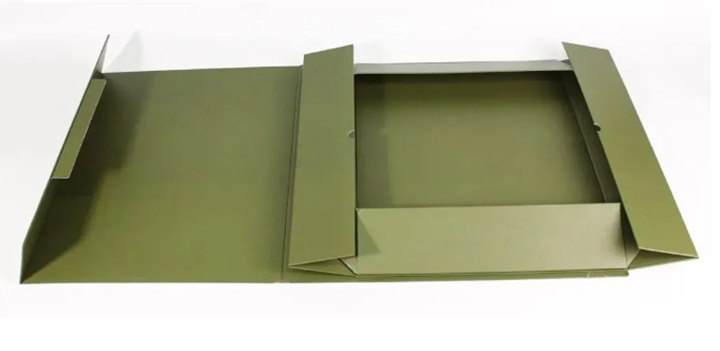

In addition to the drawer box, there is also a double-open structure of high-end folding gift box. They are easy to open and close, the left and right covers can also be folded and flattened after opening, and the side of the inner box is folded and flattened, which facilitates storage and transportation, saves labor costs, and is very cost-effective.

The triangular folding packaging boxes generally adopts a one-piece structural design, the opening and closing are closed with magnets, and the outer handle can use paper handles, ribbons, etc. The unique triangular shape gives a unique feeling and completely subverts the shape of the traditional box.

1. Structural design, draw the size diagram of the box. You just need to tell us the dimensions of the products you need to package, and our designers will use professional drawing software, such as AutoCAD or Adobe Illustrator, to draw detailed structural sketches.

2. Paper cutting and printing: Large rolls of cardboard must be cut into individual sheets before they can be sent into the printing machine. Use a printing machine to print the designed patterns and text onto paper. Common printing methods include offset printing, flexo printing, etc. Offset printing is suitable for high-quality, multi-color printing needs and can present rich color levels; flexo printing is often used for simple patterns and large-area solid color printing.

During the printing process, it is necessary to control the color, concentration, drying speed and other parameters of the ink to ensure stable printing quality.

3. Surface treatment, die cutting and indentation

After printing, surface treatment will be performed, such as lamination (glossy film can increase gloss, matte film can give the surface a matte effect), glazing (improving surface gloss and wear resistance) or UV treatment (enhancing the three-dimensional sense of the pattern) and wear resistance) etc. Die-cutting is to use a die-cutting knife to cut the paper according to the designed shape to form all sides of the box. Creasing is to press folding lines on the paper to facilitate subsequent folding operations.

4. Fold, stick or lock

Fold the die-cut paper according to the indentation line to form the preliminary shape of the box. Our company uses automated folding equipment to ensure folding accuracy and efficiency. Paste all sides of the folded box (using glue) or use a locking structure (such as tongues, buckles, etc.) to assemble a complete folding packaging boxes.

5. Quality inspection

Conduct a comprehensive inspection of the produced folding packaging boxes. The inspection includes whether the dimensions meet the requirements (measured using measuring tools), whether the printing is clear and accurate, whether the surface treatment effect is good, whether the assembly is firm, etc.

6. Pack for qualified folding packaging boxes. Generally, they are packaged individually in perforated plastic bags and then in double-corrugated outer cartons.

1. Our company has complete automation equipment. Our company has 3 fully automatic forming machines, 3 fully automatic cartoning machines, and 3 fully automatic leather shell machines. The daily production capacity is 30,000 pieces, which greatly reduces labor costs. If your order quantity is large and the demand is urgent, you can choose to cooperate with us.

2. In addition to the above-mentioned automated equipment, our company also has 3 manual operation lines. For some products with high quality requirements and small batch orders, our company will arrange manual production. Flexible arrangements to meet the requirements of different customers is another advantage of our company.

3. Strict quality management system. Our company will arrange quality inspection to strictly control everything from raw materials to manufacturing process to finished products. Especially for finished products, we can achieve 100% full inspection.

Ordinary specifications, simple craftsmanship, small batches: If it is of general size (such as common jewelry boxes, cosmetic sample boxes and other smaller sizes), use ordinary paper material (such as 250-300 grams of white cardboard), and the craftsmanship is relatively simple (only simple printing, no special surface treatment), small batch customization (such as about 500 pieces), the price of a single rigid paper folding box may be around $0.5-$1.5.

Medium size, conventional process, medium batch: For medium size (such as common shoe boxes, electronic product packaging boxes, etc.), the material is better cardboard or special paper, and the process includes conventional surface treatments such as offset printing and hot stamping. The batch size is 500 - Around 1,000 pieces, the price of a single box may be $1.5-$4 .

Large specifications, complex processes, large batches: If it is a large size (such as large gift boxes, electrical appliance packaging, etc.), the material is high-quality cardboard or composite paper, and the process is complex (such as a combination of multiple printing methods, special texture processing, high required die-cutting, etc.), and the batch size is large (more than 1,000 pieces), the price of a single box may be more than $4.5. For example, some specially customized large rigid paper folding gift boxes may cost more than $7 each.

Foldable rigid box are suitable for many industries. It is very commonly used in the food industry. Pastries, candies, etc. are packaged in foldable rigid box, which are convenient and beautiful, and can also protect the food. The cosmetics industry is also inseparable from foldable rigid box. Small items such as lipsticks and facial creams are placed in exquisite foldable rigid box to enhance their quality. In the electronic equipment industry, such as accessories packaging for mobile phones, headphones, etc., foldable rigid box are lightweight and environmentally friendly. It is also suitable for the pharmaceutical industry. Some small-dose medicines are packaged in foldable rigid box for convenient storage and transportation. There is also the toy industry. Various small toys are packaged in foldable rigid box, which can be printed with cute patterns to attract children. In short, foldable rigid box can come in handy as long as the products need to be easily packaged, transported and displayed.

If your product belongs to the above industries, please communicate with us. If it does not belong to the above industries, our foldable rigid box may also provide you with customized solutions. If you want to know more about hard foldable rigid box, please Contact us.

We chat